Do-It-Yourself Noise Control Materials

THERE ARE THREE BASIC WAYS TO REDUCE NOISE IN MOST APPLICATIONS

- ABSORPTION

Materials that absorb noise have an open fibrous structure that allows sound to enter. The internal strands or fibers of the material vibrate, and the resulting mechanical movement dissipates the energy in the form of a minute amount of heat. Absorbing materials are used to reduce the reverberant noise build-up from inside buildings, rooms, working spaces or equipment housings. - BLOCKING

Blocking materials provide a barrier to noise. Blocking materials do not absorb or deaden noise, but rather block the direct path of the noise by reflecting it away from the receiver. Performance is based on the mass and density of the material. The greater the mass and density, the better the barrier. Blocking materials can be used as a barrier to enclose the noise source or as a barrier to enclose the potential receiver of the noise. - DAMPING

Damping materials reduce noise radiation from metal surfaces by damping the vibration of the metal. This applies to both continuously radiating surfaces as well as those with intermittent metal impact. Damping materials are applied directly to the surface of a vibrating structure and will convert the mechanical vibrating energy of the surface to heat. The minute flexing of the damping material provides the energy dissipation to reduce noise. The materials are a cost-effective way to eliminate the ringing sound of vibrating sheet metal or the irritating impact noise in conveyor chutes or bins.

| Method of Noise Reduction | Product | Applications |

|---|---|---|

| Absorption | Acoustical Foam |

|

| Ceiling Absorbers |

| |

| Ceiling Tiles |

| |

| Wedge Foam |

| |

| Blocking | Vinyl Curtain and Fibersorb Curtain |

|

| Pneumatic Silencers |

| |

| Damping | Damping Tile and Damping Compound |

|

| Product | Applications |

|---|---|

| Absorption | |

| Acoustical Foam |

|

| Ceiling Absorbers |

|

| Ceiling Tiles |

|

| Wedge Foam |

|

| Blocking | |

| Vinyl Curtain and Fibersorb Curtain |

|

| Pneumatic Silencers |

|

| Damping | |

| Damping Tile and Damping Compound |

|

Soundscreen™ Acoustical Ceiling & Wall Baffles

Applications

- Wall-mounted baffles

- Ceiling-suspended baffles

- Excellent alternative to drop-in ceilings

- In-plant ambient noise reduction

- Manufacturing facilities

- Gymnasiums

Features

- NRC up to 0.94

- Easy to install

- Tuned for low to mid frequencies

- Durable and Easy to clean

- Moisture resistant

- Custom designs available

- McGill AirSilence's Soundscreen acoustical ceiling and wall baffle (ACWB) is a scrim-wrapped, highly efficient, tuned baffle designed for mid to low frequency noise absorption. The ACWB consists of a semi-rigid fiberglass core completely encapsulated within a 2-mil-thick, reinforced foil/polypropolene cover.

- The ACWB is available in standard sizes up to 4 feet by 8 feet, and in thicknesses of 1 inch (ACWB-1) and 2 inches (ACWB-2). NRCs are 0.75 and 0.94, respectively, when tested in a number 4 mounting (direct mounted). The ACWB has flame spread and smoke spread developed ratings of 5 each making them suitable for applications requiring low flame and smoke emissions.

- These board-like baffles provide good structural integrity and are damage resistant. They can be used in temperatures ranging from -40°F to 450°F.

| Acoustical Performance | ||||||||

|---|---|---|---|---|---|---|---|---|

| Model | 1/3 Octave Band Center Frequency (Hz) | NRC | ||||||

| 125 | 250 | 500 | 1,000 | 2,000 | 4,000 | 1K | 2K | 4K |

| ACWB-1 | 0.13 | 0.32 | 0.95 | 1.08 | 0.62 | 0.46 | 0.75 | |

| ACWB-2 | 0.26 | 0.80 | 1.23 | 1.00 | 0.71 | 0.43 | 0.94 | |

| Physical Properties | |||||||

|---|---|---|---|---|---|---|---|

| Product | Weight (lb/ft2) | Thickness (in) | Thick (in) | Service Temp. (°F) | Permeance (MVTR) | Puncture Resistance Beach | Tensile Strength (PSI) |

| ACWB-1 | 1.5 | 1 or 2 | -40 to +450 |

0.02 (ASTM E-96) Dry Cup, Proc. A Perms. Max |

100 (ASTM D-781) |

40 (ASTM D-828) | |

| Flammability Properties | |

|---|---|

| ACWB-1 |

E-84 Surface Burning Characteristics of Building Materials: Meets Class A Rating: Flame Spread Index = 5, Smoke Density Index = 5 |

| Environmental Testing | |

|---|---|

| Weather Resistance | No corrosion or delaminating at 120°F, 95% relative humidity for 30 days. |

| Temperature Resistance | Laminate withstands 4 hours at 150°F without delaminating |

| Water Resistance | Withstands 24 hours water immersion at 70°F without delaminating |

| Cold Weather Flexibility | At -40°F passes with no cracking of the polypropylene surface (ASTM D-1790) |

| Dimensional Stability | A.D. ± 0.125%, M.D. ± 0.125% |

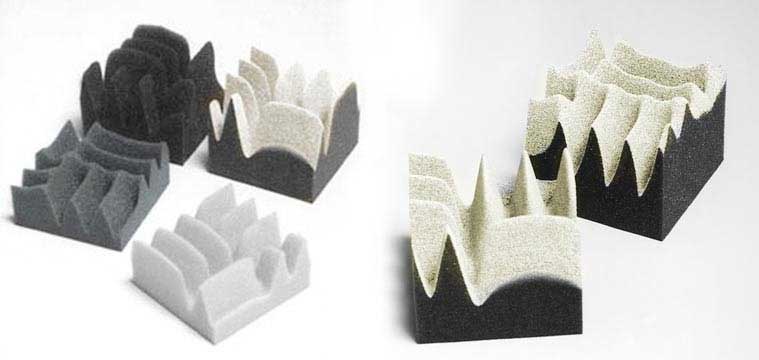

Soundscreen™ Wedge Foam

Fire Retardant

- Our fire-retardant Class 1 wedge foam can withstand constant temperatures up to 302°F and short-term temperatures up to 482°F. It meets tough government fire codes for schools, churches, and laboratories. Like Soundscreen standard Wedge Foam, our 2- by 4-foot sheets of fire-retardant foam can easily be cut to fit smaller spaces.

- A Hypalon® coating my be applied to the foam surface to repel oil, acid, and solvents. The Hypalon coating makes the foam washable.

WEDGE FOAM ABSORBS NOISE IN INDUSTRIAL AND COMMERCIAL ENVIRONMENTS

Soundscreen wedge foam is made specifically to absorb reverberant noise in manufacturing plants, offices, and recreational facilities.

The foam's patented wedge shape provides 450 percent more surface area to absorb noise than the flat surface of regular foam. The wedge shape is also a design element; it creates a clean and modern look when installed. The extra surface area and aesthetic appeal of wedge foam make it an ideal noise control solution for public area. Custom colors are available.

The frequency of noise to be controlled determines how thick the foam should be. Lower frequency noise is controlled best with thicker foam. Refer to the Sound Absorption Coefficient chart to see how 2- and 4-inch-thick foams behave when subjected to various noise frequencies.

Installation is easy. Use a utility knife to cut the foam on its flat side, then attach it to walls or partitions with a fast-tacking contact cement.

| Acoustical Performance | ||||||||

|---|---|---|---|---|---|---|---|---|

| Model | 1/3 Octave Band Center Frequency (Hz) | NRC* | ||||||

| 125 | 250 | 500 | 1,000 | 2,000 | 4,000 | 1K | 2K | 4K |

| Standard 2* | 0.08 | 0.25 | 0.61 | 0.92 | 0.95 | 0.92 | 0.70 | |

| Standard 4* | 0.20 | 0.70 | 1.06 | 1.01 | 1.01 | 1.00 | 0.95 | |

| Class 1 | 0.16 | 0.34 | 0.81 | 1.00 | 0.99 | 0.97 | 0.80 | |

| Class 1** | 0.18 | 0.65 | 1.04 | 0.73 | 0.68 | 0.56 | 0.80 | |

| *Noise Reduction Coefficient **With Hypalon® coating | ||||||||

| Physical Properties | Standard Foam | Class 1* / Class 1 with Hypalon** |

|---|---|---|

| Material | Open-cell polyester urethane foam | Pourous acoustic melamine |

| Size | 2' by 4' sheets | 2' by 4' sheets |

| Thicknesses | 2", 3" and 4" | 2" |

| Colors | Brown, charcoal, and beige | white*, white**, gray**, black** |

| Density | 2.0 lb/ft3 | 0.7 lb/ft3 |

| Tensile Strength | 20 psi | 8 psi |

| Flammability | UL-94HF-1 | UL-94V-0 |

| Flame Spread | 95 | 5* / 185* |

| Smoke Density | 340 | 45* / 185* |

| *Class 1 **With Hypalon® coating | ||

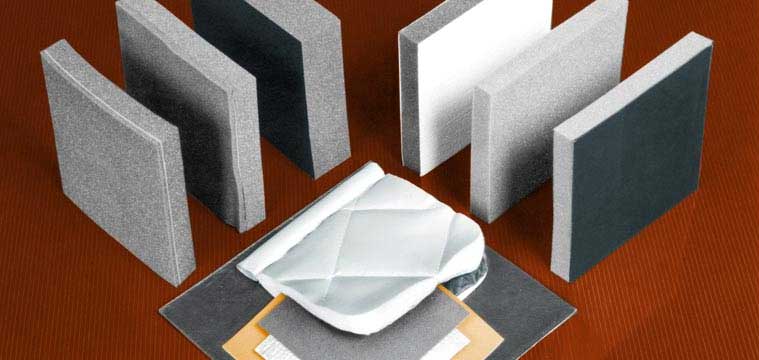

Soundscreen™ Acoustical Foam

Installation

- Acoustical foam is a light-weight cellular plastic material with high tear and shear strength. The material is easily trimmed to size with a knife or scissors. The most common attachment method is a solvent base contact adhesive. Mechanical pin fastening can make some difficult overhead surface applications easier.

- Pressure sensitive adhesive (PSA) backing is available but not recommended for custom projects or low volume useage. A PSA installation system is usually only cost effective when the savings in production line labor exceed the adhesive's premium cost. PSA is not recommended for use where service temperature exceeds 150°F or where high humidity or oil mist is present.

- ACOUSTICAL FOAM KEEPS REVERBERANT NOISE LEVELS LOW

Soundscreen Acoustical Foam is a 2 lb/ft3 density flexible polyurethane polyester foam. The open cell construction provides an attractive non-reflective surface that absorbs airborne noise. The charcoal gray foam is a safe, non-toxic pleasant handling material that's easily cut with a knife, scissors, or steel rule die. - PRODUCT FACING SELECTION

- Plain Unfaced Foam (FOA-P): This basic acoustical grade foam from which all versions are derived, is excellent for clean, non-abusive applications, such as business machine enclosures.

- Clear Polyester Facing (FOA-C): The lowest price facing that effectively protects the open cell foam structure from dirt, moisture, lubricants, and similar contaminants. It is recommended for applications where charcoal gray is aesthetically acceptable.

- White Polyurethane Facing (FOA-U): A mid-priced, slightly tougher facing. Recommended for applications where the aesthetics of a cleanable white surface are as important as the facing's contaminant and abuse resistance properties.

- Perforated Vinyl Facing (FOA-V): Best suited for applications such as vehicle cabs or equipment enclosures where durability and decorativeness of the black vinyl surface is needed.

| Acoustical Properties: Absorption Effectiveness | ||||||||

|---|---|---|---|---|---|---|---|---|

| Foam Thickness | Frequency (Hz) | NRC* | ||||||

| 125 | 250 | 500 | 1,000 | 2,000 | 4,000 | 1K | 2K | 4K |

| 1" | 10% | 28% | 71% | 100% | 91% | 95% | 0.73 | |

| 2" | 30% | 66% | 92% | 99% | 100% | 100% | 1.00 | |

| Values are representative for random incidence test per ASTM C423. Effectiveness will vary with facing selected. | ||||||||

| Physical Properties of Basic Foam | ||||

|---|---|---|---|---|

| Density | Tensile Strength (psi) | Tear Strength (psi) | Elongation | Color |

| 2.0 ± 10% | greater than 17.0 | greater than 1.6 | greater than 130% | charcoal gray |

| Product Availability | ||||

|---|---|---|---|---|

| Model | Thickness (psi) | Size* | Type of Foam Facing | |

| FOA-P1 | 1" | 50' roll | uncovered | |

| FOA-P2 | 2" | 10' sheet | uncovered | |

| FOA-C1 | 1" | 50' roll | clear polyester | |

| FOA-C2 | 2" | 10' sheet | clear polyester | |

| FOA-U1 | 1" | 50' roll | white polyurethane | |

| FOA-V1 | 1" | 50' roll | perforated vinyl | |

| *All rolls and sheets are a nominal 54" wide. Trimmed and die cut sheets are available. Please specify. | ||||

| Flammability Properties of Basic Foam | ||

|---|---|---|

| Application | Test Method | Classification |

| Component Plastics | UL-94 | HF-1 |

| Component Plastics | ASTM D-1692 | self-extinguishing |

| Motor Vehicle Interiors | MVSS 302 | SEO |

| Different film facings and adhesive systems will affect this flammability classification of the applied product. | ||

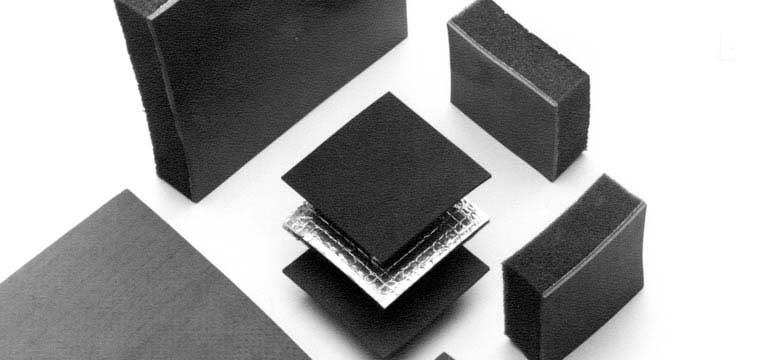

Soundscreen™ Noise Dampining Sheet & Tile

Typcial resonating vibration noise applications:

- Fan and blower housings

- Equipment cabinets

- Duct and pipes

- Machine tools

- Computer cabinets and consoles

- Doors and panels

Typcial impact noise applications:

- Vibratory

- Chutes

- Parts tumblers

- Bins

- Conveyors

- NOISE DAMPING SHEET AND TILE ARE COST EFFECTIVE

Soundscreen Damping Tile is made of an extruded polymer composite of vinyl and graphite which has superior damping performance. This versatile material is avaiable in 0.035- through 0.580-inch thicknesses. The thin sheets can be inexpensively furnished in volume quantities, die-cut with or without high-quality pressure sensitive adhesive backing. Thicker 1/4- and 1/2-inch tiles are exceptional noise damping treatments for steel plate and fabricated plate structures.

The 2- by 4-foot sheets of 0.062-inch-thick material with a bonded layer of Soundscreen Acoustical Foam form a unique acoustical liner. The foam absorbs reverberant noise, and the damping reduces radiated noise. - ADHESIVE APPLICATION

Thicknesses up to 0.0125 inches are available with an acrylic-based, pressure-sensitive adhesive backing (PSA). This PSA combines high initial tack and a high degree of permanence. Peel strength is a minimum 6 pounds/inch per ASTM-D903-49 test specification.

The preferred adhesion method for all thicknesses of tile are a 100 percent solids epoxy or a two-part urethane adhesive. To ensure a strong bond, follow the adhesive manufacturer's application instructions.

| Physical Properties | |

|---|---|

| Density | 95 ± 5 lb/ft3 |

| Solids Content | 100% |

| Color | Black |

| Flame Retardance | Self-extinguishing (ADTM D-635) |

| Flame Point | In excess of 400°F |

| Oil and Water Resistance | Good |

| Appearance | Smooth surfaces with no foreign substances to hinder adhesion |

| Operating Temperature Range | Effective in the range from 35°F to 100°F, with maximum loss factor of 0.8 in the band from 65°F to 100°F |

| Product Availability | ||

|---|---|---|

| Model | Thickness | Size |

| DM-035-1 | 0.035" | 12" x 12" tile |

| DM-062-1 | 0.062" | 12" x 12" tile |

| DM-125-1 | 0.125" | 12" x 12" tile |

| DM-375-1 | 0.375" | 12" x 12" tile |

| DM-500-1 | 0.500" | 12" x 12" tile |

| DM-625-1 | 0.580" | 12" x 12" tile |

| DM-035-2.5 | 0.035 | 12" x 30" sheet |

| DM-062-4 | 0.062" | 24" x 48" sheet |

Soundscreen™ Vinyl Noise Barriers & Mats

Installation:

- The 1/8-inch-thick loaded vinyl comes in rolls and can be easily cut with a knife, shears, or steel rule die. When suspended from an existing wall or partition, the vinyl should be pinched between bolted support strips and suspended from a suitable structural support.

- For curtain applications, a grommeting kit (Soundscreen GK-1) containing a tool and grommets is available for economical self-installation. Grommets should be spaced on maximum 12-inch centers, and adjacent sections can be overlapped 6 inches to reduce acoustical leakage.

- A variety of methods can be used to acoustically seal overlapping seams. For flashing existing partitions up to a ceiling, the adjoining vinyl sheets can be riveted or bolted together. For custom-designed curtain enclosures and barriers, Velcro® strips can be sewn onto the vinyl edges to provide a positive sealing mechanism.

- Loaded vinyl contains a plasticizer ingredient that can create adhesion problems. For applications where an adhesive seal is appropriate, using a two-part urethane is recommended.

- SOUNDSCREEN VINYL NOISE BARRIERS EFFECTIVELY BLOCK AIRBORNE NOISE

Soundscreen Vinyl Noise Barrier is flexible fused vinyl sheet material loaded with high density inert fillers. This combination of materials provides the limpness and mass necessary for the effective blocking of airborne noise. Easy to cut and install, the material may be laid on floors, draped over uneven surfaces or suspended as a curtain wall. - STANDARD PRODUCTS

- Reinforced Loaded Vinyl (LVR): The basic 1/8-inch-thick, 1 lb/ft2 density loaded vinyl is reinforced in the center with a polyester scrim. Use in all hanging or other applications where superior integral material strength is needed.

- Clear Vinyl (LVC): Used as a transparent curtain or as a window in a curtain enclosure, standard LVC is 0.08 inches thick to 0.5 lb/ft2 density. Where required, 0.75 and 1 lb/ft2 densities can be furnished.

- Plain Black Reinforced (LV): Our lowest-cost LV bonds to sheet metal or plywood to make machinery covers or walls. Lay it under rugs or over ceilings to cut down on noise transmitted into plant offices.

- Floor Mat (FVM-1 or FVM-1S): Unreinforced black loaded vinyl with a 1/4-inch backing of decoupling foam fused to LV. It is used on floors, bulkheads, and side panels to cut down road, engine, and drive train noise. Plain surface model (FVM-1) is coated with a scuff-resistant vinyl to improve wear resistance (FVM-1S).

| Acoustical Properties | ||||||||

|---|---|---|---|---|---|---|---|---|

| Foam Thickness | Typical Sound Loss in dB | STC | ||||||

| 125 | 250 | 500 | 1,000 | 2,000 | 4,000 | 1K | 2K | 4K |

| 1 lb/ft2 LV and LVR | 15 | 19 | 21 | 26 | 33 | 37 | 27 | |

| 0.5 lb/ft2 LVC | 8 | 19 | 16 | 21 | 25 | 30 | 20 | |

| Physical Properties | ||||

|---|---|---|---|---|

| Product | Thickness and Weight | Temperature Range (°F) | Color | Resistance (all products) |

| LVR | 1/8", 1 lb/ft2 | 0 - 180 | black |

water: excellent petroleum: excellent alkalis: good flame: meets MVSS 302 |

| LV | 1/8", 1 lb/ft2 | 0 - 180 | black | |

| LVC | 0.08", 0.5 lb/ft2 | 0 - 120 | clear | |

| Product Availability | ||

|---|---|---|

| Model | Roll Size | Vinyl Description |

| LVR | 54" x 60" | gray, reinforced vinyl |

| LVC | 48" x 60" | clear vinyl |

| LV | 54 x 60" | black, unreinforced vinyl |

| FVM-1 | 54" x 60" | black, vinyl floor mat |

| FVM-1S | 54" x 60" | black, vinyl floor mat with scuff coating |

Soundscreen™ Acoustical Lining

Installation:

- Both Foam/Vinyl/Foam and Foam/Damping materials can be cut with standard sheet metal shears. The linings can also be readily supplied as die cut pieces ready for installation into equipment housings.

- Barrier linings must be bonded to the structure by their 1/4-inch-thick compliant foam layer. A solvent-based contact adhesive is a proven adhesion method.

- The preferred adhesive for Foam/Damping linings is a two-part epoxy.

- Foam/Damping linings with pressure sensitive backing on the damping sheet is also available. This is not recommended for critical damping applications where service temperature exceeds 150°F or where high humidity or oil mist is present.

- SOUNDSCREEN ACOUSTICAL LINING PROVIDES ABSORPTION AND DAMPING

Soundscreen Acoustical Lining combines several basic noise control materials into a simple, multi-layered, acoustical composite material. Two basic linings satisfy most applications: absorbing foam plus noise barrier, and absorbing foam plus damping. Acoustical liners convert bare metal into effective noise enclosures by adding the right combination of sound deadening material to the inside surfaces. - PRODUCT SELECTION

- Foam/Vinyl/Foam Barrier Lining: This barrier lining is available with 1 lb/ft2 density loaded vinyl and is the same as the inner septum layer. This lining material is excellent for building factory partitions. Adhered to 1/4-inch plywood, the material provides approximately 50 dBA transmission loss at the critical 1000 and 2000Hz frequencies — equivalent to the noise reduction of an 8-inch masonry block wall!

- Foam/Damping Lining: Foam/Damping is a sheet of absorbing foam bonded to a layer of 0.062-inch-thick Soundscreen LD-400 damping material. The material reduces the humming noise associated with vibrating sheet metal, as well as controls the reverberant noise inside cabinets or equipment covers.

- As a combination of materials, each layer of the product serves a specific function. The 0.062-inch-thick layer of LD-400 damping material effectively controls radiation noise in metal up to 16-gauge thickness. The damping material is bonded directly to the metal structure for maximum effectiveness. The 1-inch thickness of acoustical foam faces the noise source so that it can absorb reverberant noise.

| Acoustical Properties: Absorption Effectiveness | ||||||||

|---|---|---|---|---|---|---|---|---|

| Thickness | Frequency Hz | NRC | ||||||

| 125 | 250 | 500 | 1,000 | 2,000 | 4,000 | 1K | 2K | 4K |

| 1" | 10% | 28% | 71% | 100% | 91% | 95% | 0.73 | |

| Acoustical Properties: Transmission Loss | ||||||||

|---|---|---|---|---|---|---|---|---|

| Frequency Hz | STC | |||||||

| 125 | 250 | 500 | 1,000 | 2,000 | 4,000 | 1K | 2K | 4K |

| 1 lb/ft2 septum | 15 | 19 | 21 | 28 | 22 | 37 | 27 | |

| Product availability | ||||

|---|---|---|---|---|

| Model | Material Composition | Matl Comp | Size | Absorbing Foam Cover Type |

|

FVF‑P FVF‑U |

1" Absorbing foam, 1 lb/ft2 vinyl septum, 1/4" foam | 54" x 50' roll | uncovered white polyurethane | |

|

FD‑P1 FD‑U1 |

1" Absorbing foam, 0.062" LD-400 damping sheet | 2' x 4' sheet | uncovered white polyurethane | |

|

FD‑P2 FD‑U2 |

2" Absorbing foam, 0.062" LD-400 damping sheet | 2' x 4' sheet | uncovered white polyurethane | |

| Other protective covering options are available. | ||||

Soundscreen™ Pneumatic Air Silencers

- SOUNDSCREEN PNEUMATIC SILENCERS CONTROL EXCESSIVE EXHAUST AIR NOISE

Control valves create a blast of noise when exhaust air is released directly to the atmosphere. Soundscreen Pneumatic Silencers control that excessive noise by reducing the velocity and turbulence of the exhaust air flow.

Simple and easy to apply, the silencers screw directly into the exhaust port of the control valve. A Pneumatic Silencer can reduce the noise from a single exhaust port from 90 dBA to about 60 dBA. That reduction is significant. Ninety dBA corresponds to the noise of a heavy truck passing just a few feet away while 60 dBA is equivalent to normal conversation at a smiliar distance. Specific noise reduction varies with each application's size, working pressure, and exhaust configuration. - Shatterproof Nautre Increases Plant Safety

Soundscreen Pneumatic Silencers have been tested at 200 psi. The maximum recommended working pressure and temperature is 150 psi and 165°F. An additional safety factor is the shatterproof nature of the silencer material. The porous body is made from tough, high-density polyethylene. The solid threaded base, made from the same grade polyethylene, is welded to the body to form an integral single piece unit. In the event of an accidental blow, the resilient, high density polyethylene prevents the silencer from shattering and sending dangerous fragments flying. - Low Maintenance

Maintenance is usually unnecessary. The porous body of the silencer is made by the same powder sintering process used in making filter materials for gases and liquids. Moderatley clean air and water will pass through the Soundscreen Pneumatic Silencer, eliminating the problem of excessive clogging. Should cleaning be required, a solvent with low flammability such as methylene choloride, is recommended. - Availability

All sizes are available for shipment from stock. Soundscreen Pneumatic Silencer model dimensions are shown below.

Nozzle Sizes Part Number Size Weight ATN-18A 1/8" NPT 1 oz ATN-14A 1/4" NPT 2 oz - Factory Tested, 85 dBA Performance

A few thousandths variation in slot gap can cause wide variations in air consumption and noise levels of nozzles. Soundscreen High Thrust Air Nozzles are individually tested and permanently set at the factory to obtain maximum thrust at an OSHA acceptable 85 dBA noise level for line pressures between 10 and 80 psig. This is a "close in" (two feet) noise level. For intermittent operation or for further distances away, the total noise exposure is significantly less.

Useful air thrust is delivered even when the nozzle is placed some distance away. Performance over distance with 60 psig is shown in the chart below.

Air thrust performance over distance at 60 psig Distance ATN-18A ATN-14A 3" 11.1 11.5 8" 10.2 11.0 15" 9.2 10.2